A seamless steel pipe, also known as seamless steel pipe, is usually a circle with no visible seams on it and a flat bottom. This type of steel pipe is most commonly used in the plumbing, heating, and ventilation industry. Seamless steel for these applications is popular for a reason: it is hollow, usually with no seams on it, and is quite durable. It is also resistant to corrosion, which makes it perfect for the environment and most industries.

This type of pipe comes in various standard thicknesses and depending on the manufacturer, can be made from various materials such as iron, aluminum, copper, brass, and nickel. The material is heat-treated to resist corrosion, which gives it excellent mechanical properties. These pipes are often coated with an anti-corrosive liquid to resist moisture from developing in the pipe during its use. Seamless pipes are ideal for transporting liquids in the industry because it has little or no mechanical properties that limit its usage. One example of this is in the oil and gas industry, where these types of pipes are widely used.

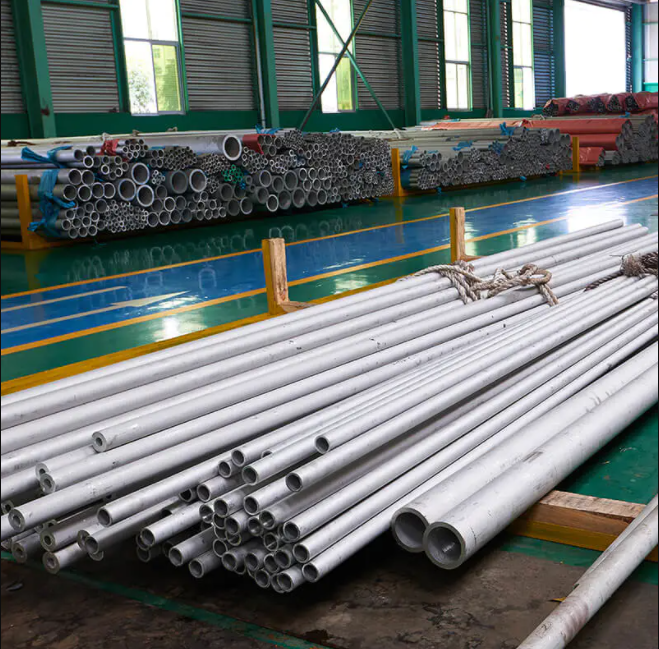

Most of these seamless steel pipe products have a round-shaped body, typically between six and 24 inches in diameter. Some products may even be produced with a hexagonal body, though this is more common. Regardless of the shape, all seamless pipes are free-flowing, as they have no two natural ends that intersect. Also, the diameter of the body will dictate how many times the pipe has been used before it must be replaced. For example, if a section of seamless steel pipe has been used over again, the diameter must be greater than one hundred twenty inches in order to prevent the pipe from coming apart.

One of the most important things to note about seamless steel pipe, or any other time for that matter, is that it must meet stringent standards before it can be sold for use. The American Society for Testing and Materials (ASTM) requires the pipe to have an external diameter of at least eighteen inches and a thickness of three and a half millimeters. In addition, the material must be formed into the appropriate Schedule STD conformations, which refers to the minimum specifications provided by the pipe. In addition to meeting both the external diameter and the thickness requirements, the material must also be free of defects.

There are two primary types of seamless steel pipe: rolled and solid. A rolled pipe consists of a series of parallel strips of material, similar to paper or cardboard. The strips are bonded together using pressure or heat to form the actual pipe. A solid pipe, on the other hand, consists of a single piece of rolled pipe. This is the most efficient, due to the fact that the pipe can be made to precision-fit to the specific diameter and depth.

Inspecting seamless steel pipes is just like seamless steel tube. It involves visual inspection of the pipe to check for internal cracking, as well as external appearance such as irregular lumps and ridges. The most important thing to check for, however, is the internal bending. Internal bending is extremely important because it indicates that the pipe has been subject to internal forces and may be prone to breakage. As with other Inspecting Processes, visual examination is the best way to determine if there are welded pipes in the pipe or not.

If you plan to buy seamless steel pipe, make sure to get your pipes from a trusted manufacturer such as Kiewa or McCulloch. These companies will provide you with the best product and service possible. For example, Kiewa manufactures all its products in the United States and has one of the highest customer satisfaction rates in the industry. Investing in Kiewa products ensures that you will get the best possible value for your money.

When it comes to selecting the right pipe, whether it be for a hot rolled seamless steel pipe or a hot rolled monel type, remember to consider the different types of welding processes. Although welded tubes have many advantages, they come with various disadvantages as well. Unscrupulous welders can strip the protective coatings off of tubes before they have been supplied to buyers. In addition, some countries (such as South Africa) do not allow for welded pipes. To ensure that your seamless steel pipe or one tube is safe for use in the United States and other countries, you should always get these tubes from a trustworthy manufacturer.