Die manufacturing is a critical process in various industries, including automotive, aerospace, construction, and consumer goods. It involves creating a die, a specialized tool used to shape or cut materials into specific forms or designs. Dies are used to produce parts with high precision and accuracy, and their manufacturing process is essential to ensure the quality and performance of the final product.

Understanding Die Manufacturing

Die manufacturing is a complex process that requires a deep understanding of the materials, tools, and techniques involved. It involves designing and creating a die that can withstand the stresses and strains of the manufacturing process, as well as the wear and tear of repeated use. The die manufacturing process is critical to ensure that the final product meets the required specifications and standards.

Die Design and Material Selection

The design of the die is critical to ensure that it produces parts with the desired shape and accuracy. The material for the die is selected based on the intended application and the type of material being processed. Dies can be made from various materials, including steel, aluminum, or tungsten carbide, depending on the intended application and the type of material being processed.

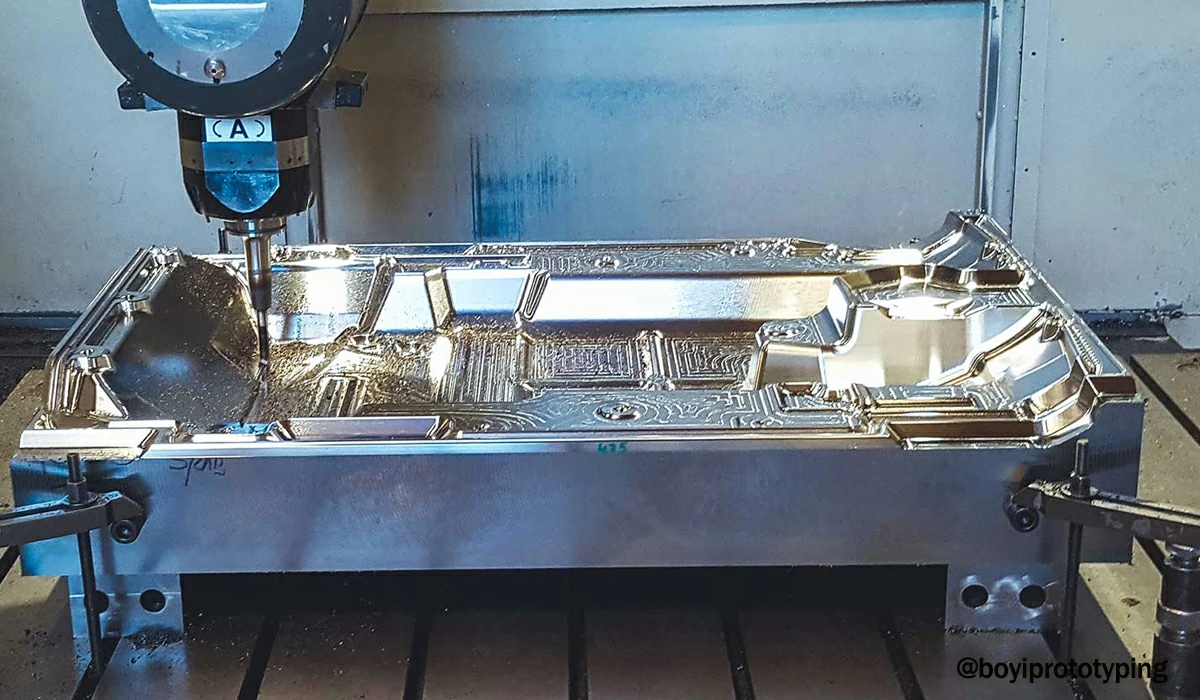

Die Machining and Finishing

The machining and finishing processes are critical to ensure the precision and accuracy of the die. The die is machined using various techniques, such as milling, turning, or grinding, to create the desired shape and design. The die is then finished by polishing or grinding its surface to achieve the desired level of precision and accuracy.

Heat Treatment and Testing

After machining and finishing, the die is heat-treated to harden its surface and increase its durability. Heat treatment involves heating the die to a high temperature and then cooling it rapidly to harden the metal. The die is then tested to ensure that it produces parts with the desired shape and accuracy.

Die Maintenance and Repair

Die maintenance and repair are essential to ensure the longevity and performance of the die. Regular cleaning and lubrication can help prevent wear and tear, while regular inspections can help identify any damage or defects.