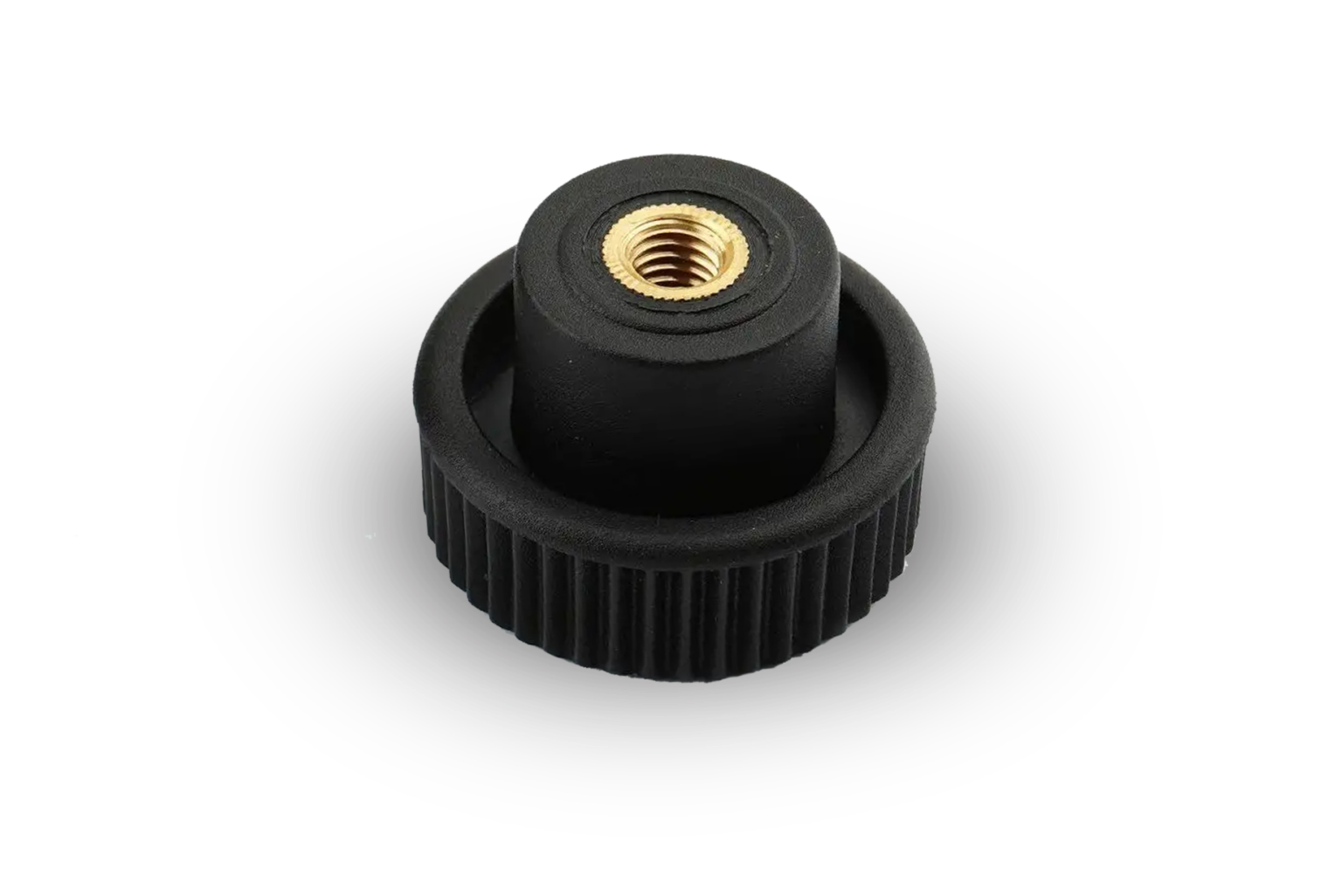

Custom insert molding is a specialized manufacturing process that combines the benefits of injection molding with the added advantage of incorporating pre-fabricated components, such as metal or plastic inserts, into the final product. This process allows for the creation of complex components with improved performance, durability, and functionality. In this article, we will explore the process and advantages of custom insert molding in detail.

The Custom Insert Molding Process

The custom insert molding process involves several steps, including design, tooling, and production. The design phase involves creating a detailed design of the component, including the type of insert material, the size and shape of the insert, and the desired bond strength between the insert and the plastic material. The tooling phase involves creating a metal mold that is precisely machined to match the design specifications.

Advantages of Custom Insert Molding

Custom insert molding provides several advantages, including improved performance and durability, reduced production costs, and increased design flexibility. By incorporating pre-fabricated components into the molding process, manufacturers can create components with precise tolerances and geometries, which is critical for many applications.

Improved Performance and Durability

Custom insert molding enables the creation of components with improved performance and durability. By incorporating multiple materials and components into a single part, manufacturers can create components that can withstand the stresses and strains of various applications.

Custom insert molding provides

A cost-effective solution for creating complex components. By reducing the need for secondary operations, such as machining and assembly, manufacturers can reduce production costs and improve efficiency and productivity. The use of custom insert molding can provide numerous benefits, including improved performance and durability reduced production costs, and increased design flexibility.

Conclusion

In conclusion, custom insert molding is a valuable manufacturing process that provides numerous benefits, including improved performance and durability, reduced production costs, and increased design flexibility. By enabling the creation of complex components with precise tolerances and geometries, custom insert molding provides a cost-effective solution for producing high-quality components. Whether you are in the aerospace, automotive, medical, or consumer electronics industry, custom insert molding can help you achieve your manufacturing goals and produce high-quality products.