In the competitive realm of manufacturing, dedicated custom mold services offer tailored approaches that optimize production efficiency and quality. These services go beyond standard offerings, focusing on custom solutions that meet the specific needs of each client. By prioritizing flexibility and innovation, dedicated custom mold services help businesses stay ahead in a rapidly changing market.

The Essence of Dedicated Custom Mold Services

Dedicated custom mold services are designed to cater to the unique requirements of various industries. These services encompass every stage of the mold-making process, from initial design and prototyping to final production and quality assurance.

Comprehensive Consultation

The journey begins with a detailed consultation between the client and the mold maker. This phase is crucial for gathering information about the project’s goals, specifications, and constraints. Key considerations may include:

Material Requirements: Understanding the properties needed for the final product.

Production Volume: Determining the scale of production to optimize mold design.

Timeline: Establishing deadlines for delivery and production.

Tailored Design Solutions

Once the consultation is complete, dedicated custom mold services focus on creating tailored design solutions. This involves:

Advanced CAD Modeling: Using cutting-edge design software to create detailed 3D models that accurately represent the final mold.

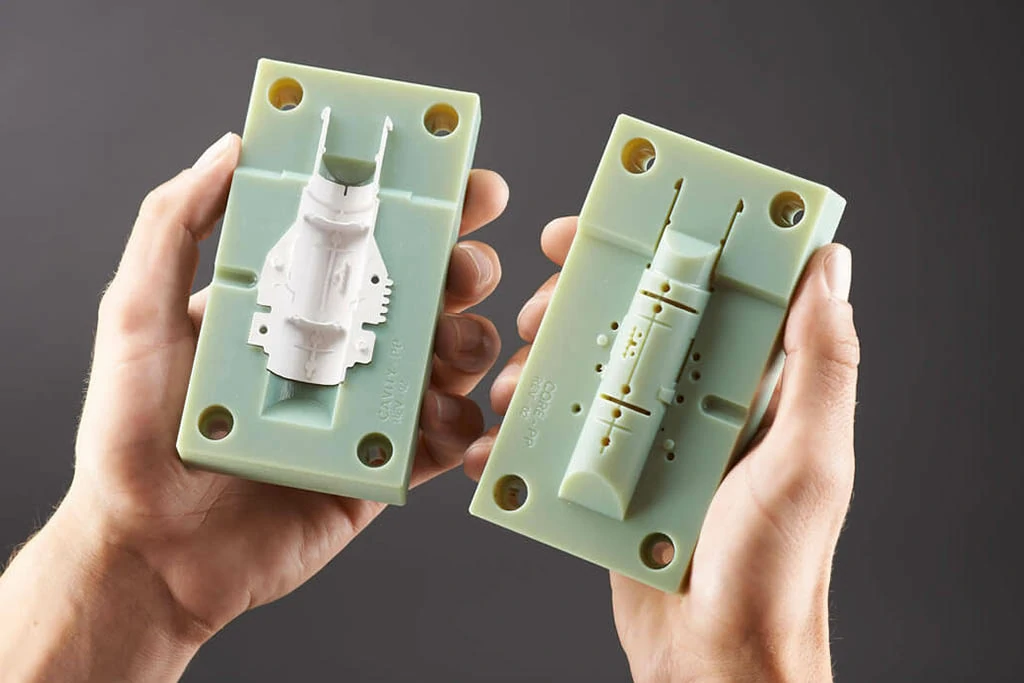

Prototyping: Developing prototypes allows for real-world testing and validation of the design before full-scale production.

Material Selection: Custom mold makers work with clients to choose the best materials, ensuring compatibility with the intended application.

The Fabrication Process

With a finalized design and selected materials, the fabrication process begins. Dedicated custom mold services emphasize precision and attention to detail:

CNC Machining: Advanced CNC machinery is used to create the mold components with high accuracy, reducing the likelihood of defects.

Assembly: Skilled technicians carefully assemble the mold, ensuring proper alignment and fit.

Testing and Validation: Before production begins, the mold undergoes rigorous testing, including trial runs to identify any issues and make necessary adjustments.

Quality Assurance Practices

Quality assurance is integral to dedicated custom mold services. Manufacturers implement comprehensive quality control measures throughout the process. This includes:

Dimensional Inspections: Ensuring that all components meet specified measurements.

Functional Testing: Validating that the mold produces parts that perform as expected.

Continuous Improvement: Gathering feedback and making iterative improvements to enhance future projects.

Industry Applications

Dedicated custom mold services find applications in various industries, including:

Automotive: Custom molds for automotive components require precision and durability to meet rigorous safety standards.

Medical Devices: In the medical field, molds must comply with strict regulations, ensuring that products are safe and effective.

Consumer Electronics: The demand for innovative and aesthetically pleasing electronic devices drives the need for custom molds.

Packaging: Custom molds create packaging solutions that not only protect products but also enhance brand appeal.

Conclusion

Dedicated custom mold services provide tailored approaches that optimize production and meet the unique needs of various industries. By prioritizing flexibility, innovation, and quality assurance, these services enable businesses to stay competitive in a rapidly evolving market. As the demand for customized solutions continues to grow, dedicated custom mold services will play an increasingly vital role in the manufacturing landscape.