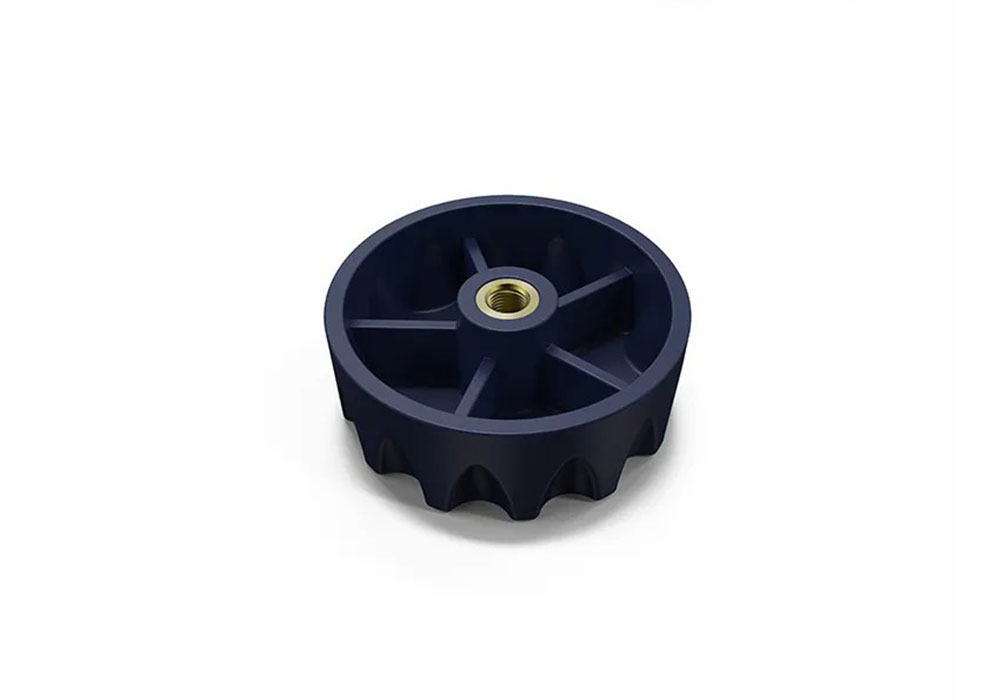

Insert molding is a specialized process that involves the encapsulation of a metal or plastic insert within a molded part. This technique allows for the creation of complex and durable components that have overlapping materials with varying properties. Custom insert molding services take this process a step further by providing tailored solutions to meet the specific needs of each individual part.

Enhancing Product Design and Functionality

One of the key advantages of custom insert molding is the ability to enhance product design and functionality. By encapsulating inserts within a molded part, manufacturers can create components that are not only stronger and more durable but also more efficient and cost-effective. This is especially beneficial for parts that require additional strength, stability, or insulation.

Precision Craftsmanship and Expertise

Custom insert molding services offer precision craftsmanship and expertise in creating parts for a wide range of industries and applications. Whether it’s automotive components, medical devices, electronics, or consumer products, custom insert molding can be tailored to meet the unique requirements of each project. This allows manufacturers to design and produce parts that are optimized for performance, quality, and reliability.

Cost Savings and Efficiency Benefits

In addition to enhancing product design and functionality, custom insert molding solutions also offer significant cost savings and efficiency benefits. By combining multiple materials in a single part, manufacturers can reduce the need for secondary operations and assembly processes. This not only streamlines production but also reduces material waste and labor costs. Custom insert molding can also improve product performance and consistency by ensuring that inserts are securely encapsulated within the molded part.

Design Flexibility and Customization Options

Custom insert molding services can also offer design flexibility and customization options that are not available with traditional molding techniques. Manufacturers can choose from a wide range of materials, colors, finishes, and textures to create parts that meet their specific aesthetic and functional requirements. Custom insert molding can also accommodate complex part geometries and intricate details, allowing for the creation of unique and innovative components.

Time-to-Market Advantages

Furthermore, custom insert molding services can provide significant time-to-market advantages for manufacturers. By working with experienced mold designers and engineers, companies can rapidly prototype and produce parts that meet their exact specifications. This can help reduce lead times, minimize production delays, and accelerate product development cycles. Custom insert molding services also offer the ability to scale production volumes quickly and cost-effectively, allowing manufacturers to meet changing market demands and customer requirements.

Conclusion

Overall, custom insert molding services offer a range of benefits that can enhance product design and functionality, improve cost efficiency, and streamline production processes. By partnering with a skilled and experienced custom insert molding provider, manufacturers can take advantage of precision craftsmanship, design flexibility, and customization options to create high-quality parts that meet their unique requirements. Whether it’s improving product performance, reducing production costs, or accelerating time-to-market, custom insert molding services can help companies achieve their goals and bring innovative products to market.