Stainless Steel Tube, (Stainless Steel). Seamless or Welded. The data and information presented herein are standard or average values used in the analysis of stainless steel pipes. When selecting tubes for installation or repair of drainage systems, it is always important to select tubes of the highest quality possible. Stainless steel is considered by many as the material of choice because it is corrosion resistant to both corrosion and stress. Further, stainless steel is not affected by many of the common operating causes of other metals such as rusting, extreme temperature changes and stress cracking.

Common piping materials include Copper, Vinyl, Plumbers and Boron and among these the most popular pipe materials being utilized are PVC, PEX, Thermosetylene, and Polyethylene. Amongst these the PVC pipe is considered the best tubing material. As a rule, the piping manufacturers offer pipe fittings of various diameters and wall thicknesses. In addition to these diameters and wall thicknesses, varying wall thickness is also available. One should ensure that the diameter of the stainless steel tube to fit within the pipe opening.

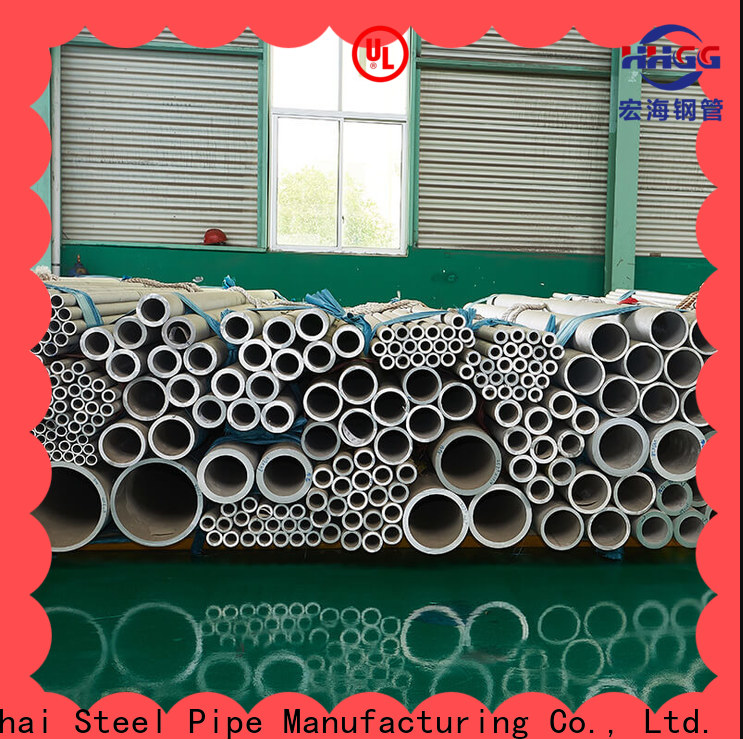

The main advantages of stainless steel tube are that its high resistance to corrosion, its exceptional tensile strength, its ductility, its ease of welding and its innate ability to maintain its integrity even under extreme working conditions. Stainless steel pipe, as an example, has an astounding range of applications. Apart from its plumbing application, it is used for constructing tanks, vessels, oil and gas pipelines, telecommunication masts, aerospace tubing and many more. A very popular type of stainless steel tube used for constructing pipelines is the round tube. The round tube or a spooled pipe is commonly used to manufacture water tanks and other forms of water pipes, specifically in the household and commercial sectors.

These stainless steel tubes are made up of high-carbon steel, which ensures their durability even under harsh conditions. They also have the property to resist corrosion resistance and at the same time maintain their clarity and color. Its distinct color gives the industrial pipe its flexibility, as it is possible to change the color whenever desired.

For manufacturing, there are various stainless steel tube options. These include the various cold rolled and hot rolled sheets. Cold rolled sheets are fabricated by placing the flat rolled sheet on a heat resistant furnace, where they are instantly formed into the exact size and shape as required. Meanwhile, hot rolled stainless tubing products are manufactured in a similar fashion but through the expedient use of a hot coil or rollers.

For those looking to purchase stainless steel tube products, there are various sources in the market. For instance, one can opt to visit online dealers who offer customized tubing options for a hassle-free purchase and delivery. One can even find ready-made tubes in varying sizes and diameters and have them delivered right at the customer’s doorsteps. In addition to this, there are online catalogs that feature various stainless steel tube items such as 304 round tubing, which is used for decorative purposes in various industries.

Stainless steel tubes are also known for their high level of corrosion resistance, making them an ideal selection for a variety of applications. These tubes are available with different external temperatures, depending on their external strength and tensile strength. The external temperatures range from low to high, and they also possess chemical resistance properties that make them suitable for use in a variety of industries.

Tubing manufacturers are also constantly striving to bring forth new products and designs. For instance, there are a number of stainless steel tubing products that feature an improved tensile strength level. This includes the use of micro-bends, micro-gaps, and other stress relieving treatments. With the help of these treatments, the durability and tensile strength of the tubing is enhanced. Such tube products also feature a machined flat top, which increases its surface area and enables the manufacturing of straighter and more streamlined joints.