Overmolding is a specialized process that involves molding one material, usually a thermoplastic, over another material to create a single multi-material component. This technique is commonly used to enhance the durability, aesthetics, and functionality of products across a wide range of industries.

Material Selection and Preparation

The overmolding process begins with the selection of suitable materials for both the base component and the overmold material. The base component, also known as the substrate, is typically made from a rigid material like metal, plastic, or rubber. The overmold material, on the other hand, is typically a softer material such as silicone, TPE, or TPV. The choice of materials depends on the specific requirements of the product, including its intended use, environmental conditions, and desired properties.

The Overmolding Process

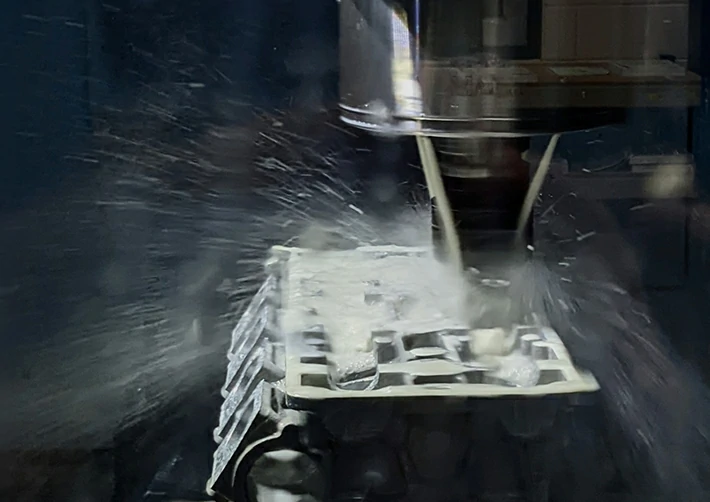

Once the materials have been selected, the overmolding process can begin. The first step involves preparing the base component by cleaning and possibly pre-treating its surface to ensure proper adhesion of the overmold material. The base component is then placed into a mold cavity, and the overmold material is injected or molded over it. The two materials are bonded together during the molding process, resulting in a seamless and integrated multi-material component.

Design Flexibility and Advantages

One of the key advantages of overmolding is the ability to create complex shapes and designs that would be difficult or impossible to achieve with traditional manufacturing processes. By molding the overmold material directly onto the base component, designers can incorporate features such as grips, ergonomic contours, and textured surfaces without the need for secondary assembly steps. This not only improves the aesthetics of the product but also enhances its functionality and user experience.

Durability and Reliability

In addition to design flexibility, overmolding also offers significant improvements in product durability and reliability. By encapsulating the base component in a protective overmold layer, manufacturers can enhance its resistance to impact, wear, and environmental hazards. The overmold material can also provide additional insulation, vibration dampening, and grip properties, further enhancing the performance and longevity of the product.

Customization and Branding

Another benefit of overmolding is the ability to customize the look and feel of the product through the use of different colors, textures, and finishes. Manufacturers can create visually appealing products that stand out in the market and reflect their brand identity. Furthermore, overmolding can be used to add branding elements, logos, and product information directly onto the component, eliminating the need for additional labeling or printing processes.

Conclusion

Overall, the overmolding process offers a cost-effective and efficient solution for enhancing product durability and design. By creating high-quality multi-material components that are both functional and aesthetically pleasing, manufacturers can differentiate their products in a competitive market and meet the evolving needs of consumers. Whether it’s improving the grip of a handheld device, adding color accents to a consumer electronics product, or increasing the weather resistance of an outdoor tool, overmolding can provide a versatile and reliable solution for a wide range of applications.