Warehouse Setup Use this setup to specify the alternatives offered through the Warehouse class in IBSS. This setup determines the division linked to recurring billing expenses, i.e. setting the warehouse on recurring billing records determines which warehouse receives the monthly revenues. You can also specify multiple warehouses linked to a specific division of service. For instance, if your organization processes automotive products, you can create a new warehouse setup that connects to the automotive department and other departments that process automotive products.

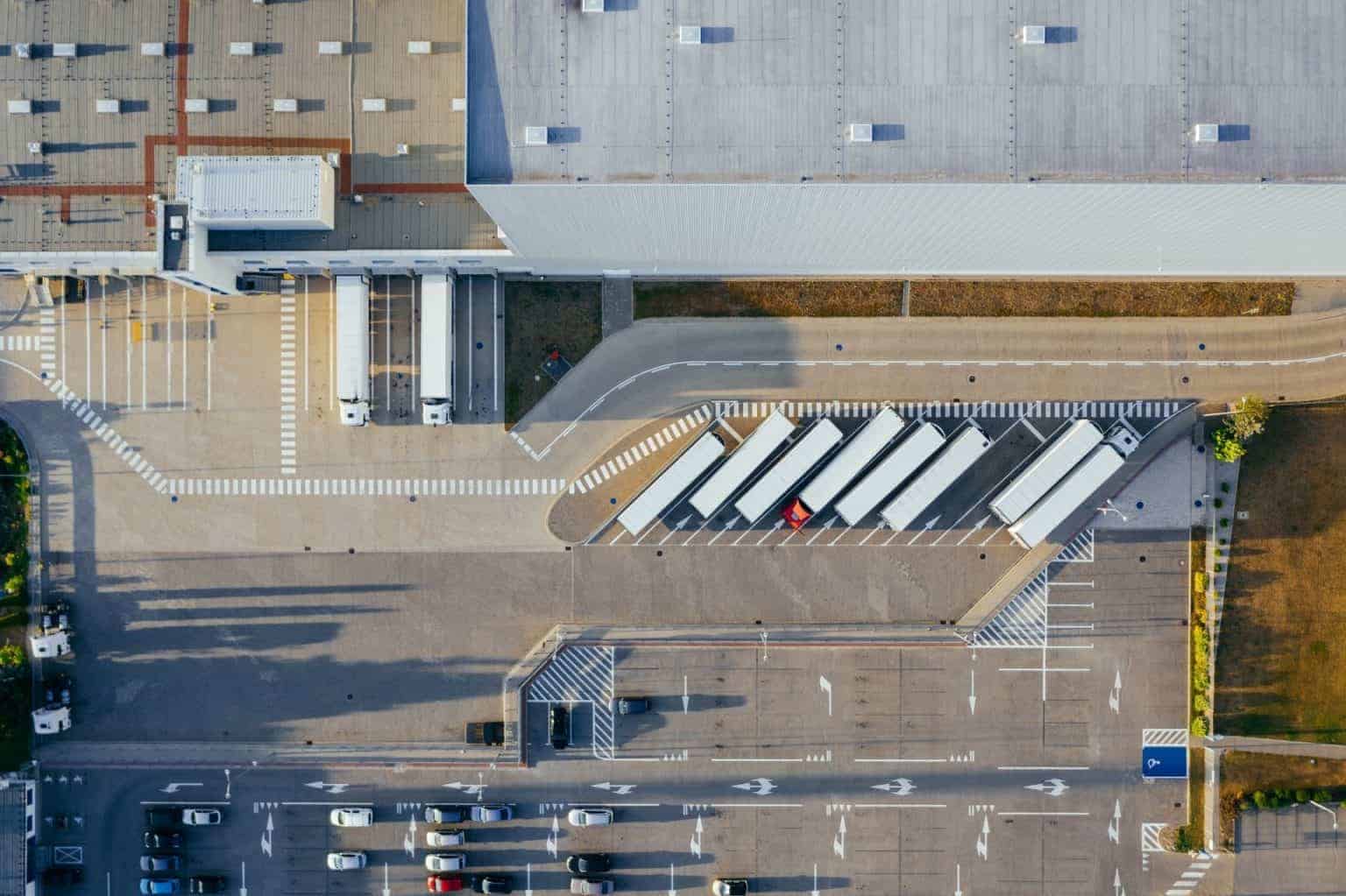

Warehouse Setup – Storing Area If you have multiple pick and place areas for the picking and storage areas, you will want to designate one area as the storing area. The area should be large enough to accommodate trucks and equipment used for picking. If you have the capacity to expand, you can create more storage areas and designate them for receiving and storing warehouse setup.

Physical Inventory Control If your warehouse is a stand-alone unit without a centralized system to manage inventory control, you need to designate one warehouse manager to coordinate the physical inventory control for all departments. The warehouse manager is responsible for determining where and how merchandise is picked and stored. To improve efficiency, staff should be trained to unload and re-load products at the appropriate times. This will ensure that there is no excess inventory or back-room merchandise sitting around. In addition, physical inventory control is essential for reducing the costs associated with over-loading, under-stocking and returns. If you want to improve customer service, assign a person from the warehouse staff to handle returns.

Shipbob Web Presence Creates a website for your organization and includes a shopping cart area where customers can add their orders. This will make it easier for customers to order online and for your employees to enter the correct shipping information. When ordering from your website, make sure to provide the correct shipping address for the item. Your website will also include a section where you can post any specials or sales that you are currently offering. Posting new inventory is a great first step in your warehouse management strategy, but this will not get you the best results.

Workflows are another important part of warehouse management. Workflows are a series of instructions and links that are connected in specific ways to increase the effectiveness of a process. There are several different workflows available, depending on the business or product you are selling. Workflows should be developed by someone who is familiar with your product and has experience developing your workflows.

Storage Areas Jars and shelves are integral parts of warehouse setup. You will need to designate appropriate storage areas for everything from finished products to finished raw materials. If you do not designate proper storage areas, the chances are good that you will be overloading your warehouse space. Proper storage areas will also help you properly transport finished products to your customers. The last thing you want to happen is to transport items to your customers and have them notice that something is missing or damaged. It can also seriously affect your reputation among your customers if your customers notice that you have inadequate storage areas when they make their deliveries.

Shipbob Port The last major part of warehouse setup is the shipbob interface and optimization. The shipbob dashboard consists of a map of all the zones of your warehouse and a list of all your stock. All of your product lines are represented visually on the map, and you can easily locate products by product type, category, or shelf position. If you have defined how many of each product line you have, you can also use these zones to create shelving and drawers. By using the appropriate icons, you can optimize storage areas to maximize productivity.

Warehouse Layout Design Once you have optimized your warehouse setup, you can begin implementing some efficient warehouse layout design. In particular, the pallet jacks you use should optimize your warehouse picking process. Using an improper warehouse picking system can greatly affect the productivity of your operation. Spend some time consulting with a pallet jack supplier to identify the best warehouse jacks for your specific needs.